Finish Technology and Process Improvements

Excellence from start to finish.

When it comes to crafting excellence, finish is vital. Our upgrades ensure a consistent, attractive appearance across products, help prevent defects, and improve customer satisfaction. The following is a checklist of changes to help Medallion deliver on our promises. Always.

Updated pour-down processes to ensure color accuracy.

WHY IT MATTERS

Updating the pour-down process improves color accuracy in cabinetry by providing a more consistent and uniform application of color or finish, resulting in:

- A more controlled application

- Minimization of imperfections

- Ensured even application

- Optimized layering of finish "steps"

- Reduced instances of human error

Onsite sprayer training conducted by Sherwin-Williams (our finish formulator).

WHY IT MATTERS

Training will be delivered directly from our manufacturer partner, providing insight and guidelines for using the finish. This will positively impact quality, efficiency, consistency, and, most importantly, improve the final result of the process. This requirement will enhance:

- Sprayer technique, reducing streaks, drips, and uneven coverage

- Paint efficiency, creating less waste and reducing overspray

- Consistency, quality, and error reduction through direct training

- Our commitment to continuous improvement through an empowered workforce

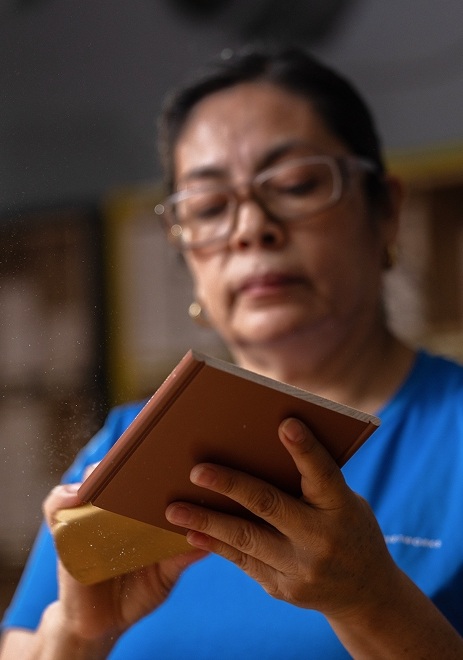

Hue test requirement for all color auditors.

WHY IT MATTERS

Not all humans see color exactly alike. By creating and requiring a "color test,” we are essentially calibrating our auditors. This helps:

- Create accurate and consistent color throughout the production process

- Eliminate color discrepancies by reducing subjectivity

- Ensure the final product aligns with customer expectations and specifications

New corporate finish quality management system.

WHY IT MATTERS

Exceptional "Finish Master Standards" is our target. It will take more than tools and process improvements — it will also require constant measurement and monitoring. Our controlled and measured process will outline:

- Frequency

- Extent

- Necessary intervals

- Specific criteria for maintaining finish standards

- More

Quarterly finish reviews.

WHY IT MATTERS

Quarterly finish reviews will be conducted at all producing sites to ensure color accuracy and alignment. This step is the formalized process that ensures our finish process and parameters. It creates:

- Continuous accountability

- Proactive issue management

- Responsibility at every level

- Scheduled scrutiny and evolution of our processes, equipment, and results

Additional improvements.

- Continued effort with Sherwin-Williams to optimize finish solutions to improve commercial finish solutions in cabinetry.

- Recurring schedule for updating finish line standards and Plant Masters to provide proof that improvements are being made.

- Enhancing color consistency by upgrading equipment and investing in industry-leading technology.

- Establishing a Sherwin-Williams material verification process.

Raising our own bar even higher.

Throughout 2025, we are making the largest investment in Medallion’s history as we fully embrace The Pursuit of Excellence. This is not just an initiative—it’s a defining moment. We look forward to delivering all of the above and then some.

Learn More About Our Improvements

Please revisit this page for further updates and details regarding our process improvements.